Not to blame for misprints or typographical mistakes. Machines proven with optional machines. True merchandise physical appearance may perhaps vary.

Introducing the Okuma LU300M, a CNC lathe recognized for its precision and high-performance abilities. This product is ideal for industries for instance aerospace and automotive due to its capability to make complex parts efficiently.

Tool paths are classified as the routes which the machine’s cutting tool follows to condition the fabric. These paths are diligently prepared to enhance efficiency and accuracy. Linear Tool Paths: Move the tool in straight lines, excellent for easy cuts.

Simultaneously, invite the identified professionals within the industry discipline to design the most recent overall look. In addition, the job staff has been completed numerous studies while in the efficiency enhance, intelligence software, humanization operation and user secondary progress, etcetera.

High quality Parts Manufacturing Constrained stands out for a pioneer in its subject, specializing in generating leading-quality CNC machining parts customized into the demands of various industries.

Our aim is to assist you to improve the lifespan and efficiency of your present tools, making it possible for you to remain competitive without the need for an entire machine alternative.

The exceptional tools and parameters improve using raw supplies and decrease off-cuts and scrap. So, efficient materials utilization lessens squander and lowers material expenses.

Continue reading to learn more and see videos from by far the most very well-recognised brand of machining centers during the industry. Make sure you Call us if you’d want to ask for a estimate or schedule a stop by with among our sales Associates. Look into our blog site, CNC Routers & Aluminum CNC Routing, To learn more!

These lathes can accomplish all milling and turning functions in one setup. They are ideal for parts that involve high precision and intricate designs, like aerospace parts.

Lathes and turning machines are also Element of CNC precision production. A CNC lathe or turning center rotates the workpiece, along with the tool moves linearly (along and throughout the function) to remove and condition the material. Consequently, They may be used to manufacture axially symmetrical items, for instance cylindrical items.

The minimized reach to your chuck can make it less complicated for machine operators to manually load and unload parts. It also allows for quicker automated (robotic) aspect loading and unloading.

Mazak Lathes stand on the forefront on the CNC machining industry, renowned for their precision, dependability, and advanced technological features. A lot of makers and machinists find used Mazak Read more lathes, used Mazak CNC lathes, and used Mazak CNC machines as feasible options to reinforce their production lines without compromising on high-quality and efficiency.

Though these machines can Reduce with just drinking water, typically extra abrasive products like garnet (a mineral) or aluminum oxide are included towards the water For additional efficient cutting.

CNC Routers: CNC routers are commonly identified for very easily cutting gentle products including wood, plastics, and aluminium to supply intricate shapes.

Haley Joel Osment Then & Now!

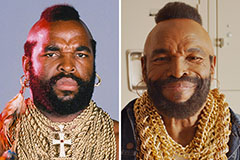

Haley Joel Osment Then & Now! Mr. T Then & Now!

Mr. T Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!